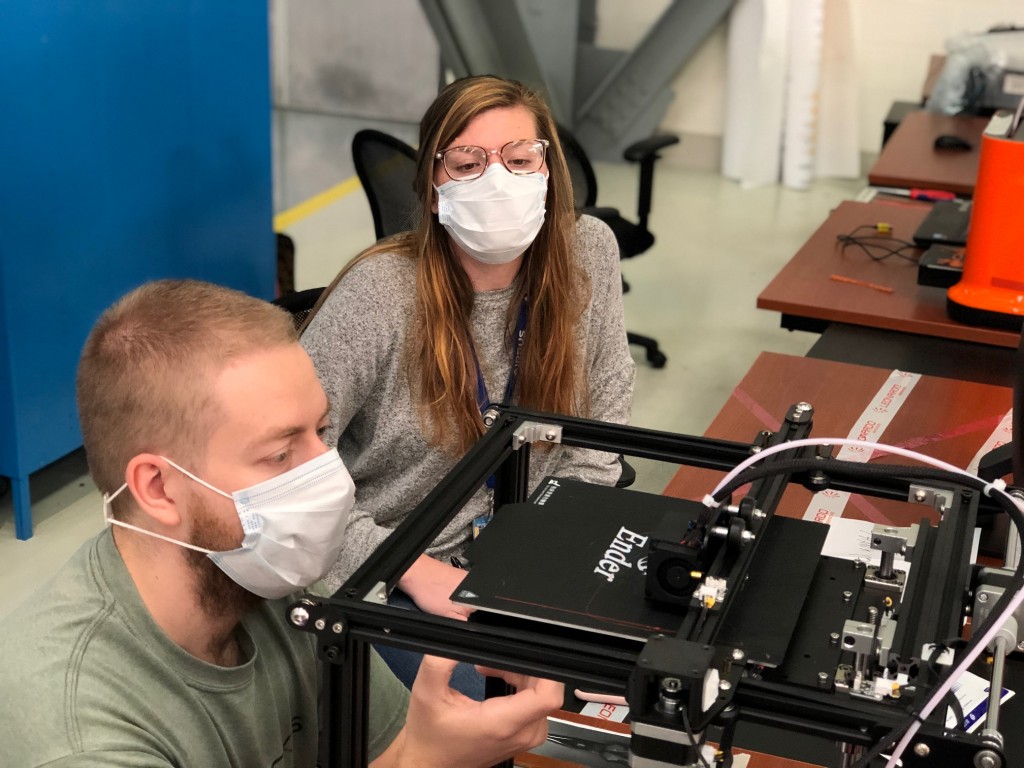

Members of the Airbus Mobile production and engineering teams have joined up with The University of South Alabama to produce 3D-printed, reusable face masks and mask tension release bands for medical personnel on the frontline of the COVID-19 pandemic. The first batch was delivered on Friday.

The team is making the masks and bands for medical personnel at USA Health, including University Hospital, Children’s & Women’s Hospital, the Mitchell Cancer Institute and the Physician’s Group. They hope to produce 500 masks, which are reusable and washable, over the next three weeks, along with approximately 75 tension release bands per day. The masks will allow conservation of personnel protective equipment by allowing multiple uses, and the bands help the masks fit more comfortably.

The masks and bands are being produced on 3D printers provided from Airbus’s production and engineering facilities, Flight Works Alabama, and the University of South Alabama, using designs from the National Institutes of Health 3D Print Exchange COVID-19 Supply Chain Response file repository.

This is only the beginning – bigger things to come soon!

This is only the beginning – bigger things to come soon!